MaNima Pollux and Pollux Industrial

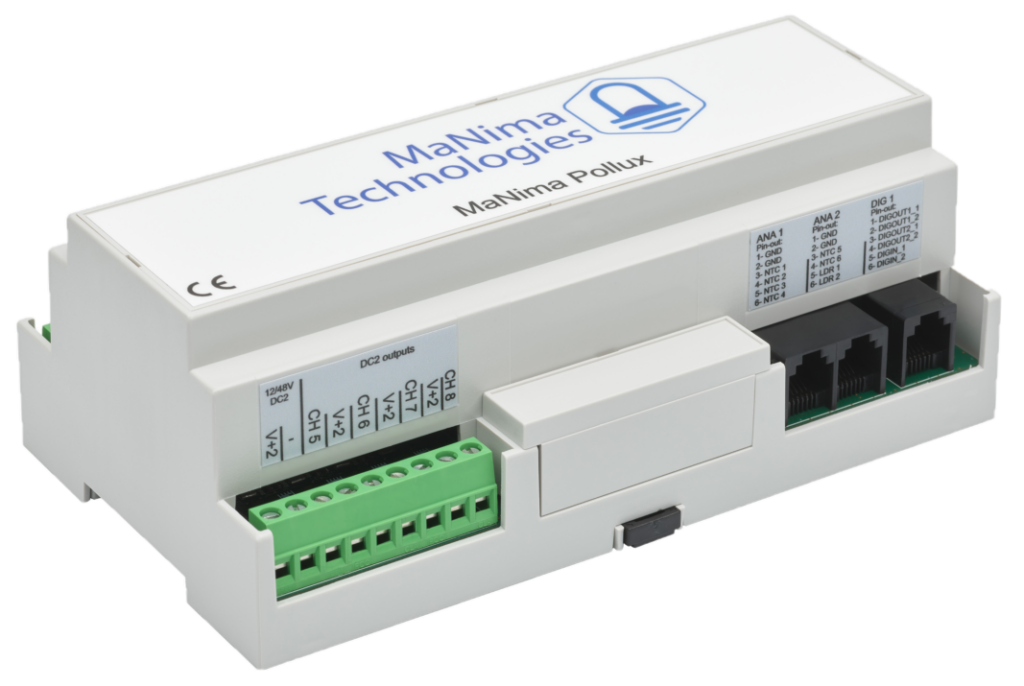

Introducing the MaNima Pollux and Pollux Industrial, an industrial PWM driver designed for robust performance in diverse applications. Operating within a wide voltage range of 12-48V, the MaNima Pollux stands out with its versatility, featuring either 4x10A or 8x5A outputs to accommodate various industrial lighting requirements.

Equipped with two Ethernet ports, the MaNima Pollux serves a dual purpose by functioning as a network switch, streamlining connectivity within industrial setups. This dual functionality enhances the overall efficiency of the system by providing a seamless networking solution directly integrated into the PWM driver.

Designed for precision and adaptability, the MaNima Pollux boasts 8 NTC inputs, ensuring precise thermal monitoring and control. This feature is crucial for industrial applications where temperature management is paramount to the longevity and reliability of electronic components.

Additionally, the MaNima Pollux features 2 digital inputs and 2 potential-free outputs, providing flexibility in interfacing with external devices and systems. The industrial version of the Pollux goes a step further with 8 ultra-fast digital inputs, enabling high-speed pulsing of the outputs. This feature proves invaluable in machine vision applications, allowing for rapid response and synchronization with high-speed industrial camera’s.

In both versions of the MaNima Pollux, a rapid hardware-based 10A short-circuit protection is integrated in each output, enhancing the safety and durability of the PWM driver. This feature ensures swift and precise response to any short-circuit events, minimizing the risk of damage to the connected components.

Furthermore, they are equipped with output current measurement and monitoring capabilities. The driver continuously measures the current flowing through its outputs, providing real-time data on power consumption. This monitoring function serves as a valuable tool for users, allowing them to set triggers for specific current thresholds. In the event that the current exceeds or falls below the predefined limits, triggers can be activated to prompt appropriate actions, such as shutting down the system or sending notifications for maintenance.

Next to all the safety issues stated above, the Pollux can be wired in a full redundant application. Both of the suppy voltages are measured and can be a source for a trigger or notification when using the MaNima Cloud. This is an extra layer of safety that the Pollux adds to your system.

The incorporation of hardware-based short-circuit protection and real-time current monitoring reinforces the MaNima Pollux as a reliable and secure solution for industrial applications. Users can have confidence in the driver’s ability to not only deliver precise PWM control but also to safeguard the connected equipment by proactively responding to potential issues in the electrical system.

Cloud connectivity

The MaNima Pollux takes industrial lighting control to new heights by seamlessly integrating with the MaNima Cloud. This integration offers users an advanced platform for monitoring and managing their LED systems, allowing for real-time insights and proactive issue resolution.

Connecting the MaNima Pollux to the MaNima Cloud opens up a world of possibilities for remote monitoring and control. Users gain the ability to oversee their industrial lighting setups from anywhere with internet access, providing a convenient and efficient means of system management.

The MaNima Cloud’s sophisticated analytics and diagnostic tools empower users to identify potential issues and anomalies in the LED system at an early stage. This proactive approach allows for swift resolution of problems, reducing downtime and optimizing the overall reliability of the industrial lighting setup.

Moreover, with the MaNima Cloud integration, users can leverage the continious current measurement and monitoring capabilities of the MaNima Pollux. Triggers can be set within the cloud platform to receive alerts when current levels exceed or fall below predefined thresholds. This real-time monitoring ensures that users are promptly informed of any irregularities, enabling them to take immediate corrective actions.

In addition to monitoring, the MaNima Cloud facilitates firmware updates for the MaNima Pollux, ensuring that the PWM driver stays up-to-date with the latest features and improvements. This remote update capability eliminates the need for on-site interventions, streamlining maintenance processes and reducing operational costs.

In summary, the MaNima Pollux, with its integration with the MaNima Cloud, offers a comprehensive solution for industrial lighting control. By providing real-time monitoring, proactive issue resolution, and remote firmware updates, this combination ensures a reliable and efficient LED system that meets the demands of industrial applications while minimizing disruptions and maximizing performance.